In confidence, we supply a solution for customer-tailored and customer-adapted powders, embodying a considerable commercial advantage. A tailored and adapted, specifically optimized powder results in a technological , competitive and commercial product. It is a quality-driven, sciencebased speciality product, not mass-produced.

For various reasons, a customer may want to hide his use of a particular powder for his competitors and therefore avoid to buy it himself. That’s why we also develop and supply customer-confidential powders: specific powders the customer asks us to buy and to supply to him only, under our responsibility.

Contact us to discuss the possibilities.

“Only your product shows your capabilities. All the rest is nice talking.”

– Dr. Ajit Shetty

Former President Janssen Pharmaceutica, a Johnson & Johnson company.

Products

All our powders are unique, innovative “science-based” speciality products, different from “chemistry-based” commodity powders.

We are involved with two types of powder:

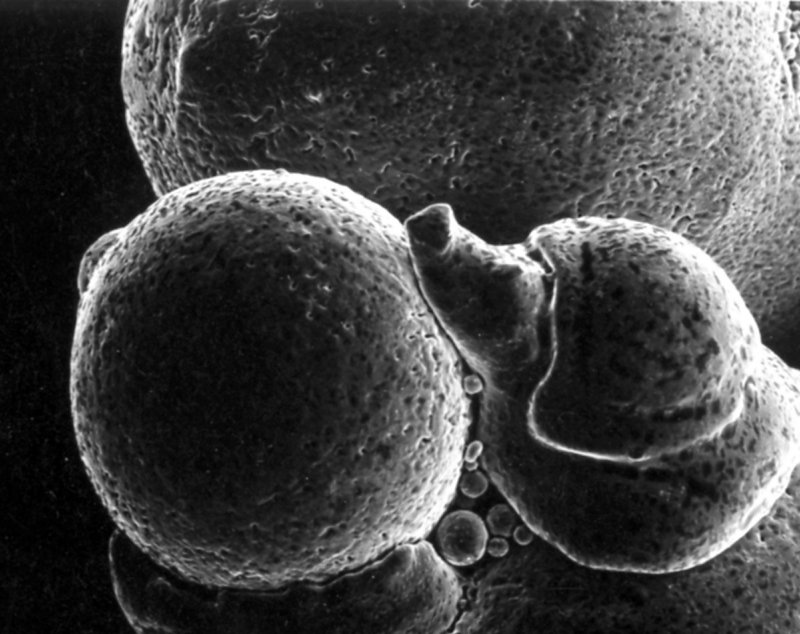

Single particle powders, non-encapsulated.

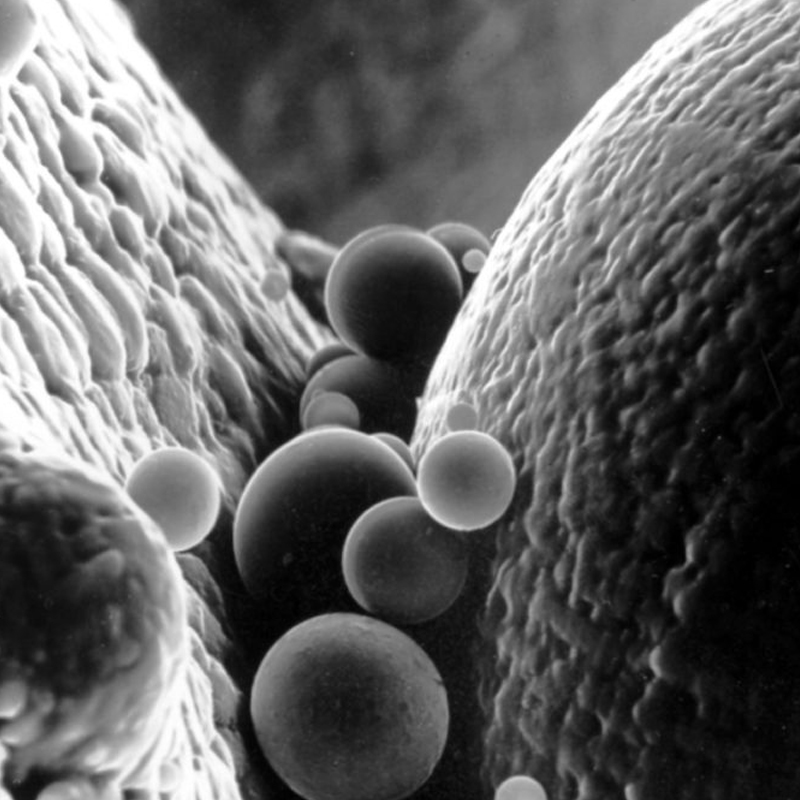

Encapsulated powders, in single, double or multiple encapsulation.

In this process, the powder particle is encapsulated with substances, giving it an additional function. This additional function can be either passive or active.

In passive mode:

– delay the reaction of the core particle, protect the core;

– strengthen the core at its use;

– conserve the core better and longer;

– time the use of the core;

– increase handling easiness;

– mask;

– and so on ….

In active mode:

The encapsulation itself starts a reaction, followed by a reaction of the core.

Tivecoma commits itself to be a reliable, competent and trustworthy partner, working together with its clients in full confidentiality. It goes without saying that specific and confidential information about the development and the manufacturing techniques of the powder, should not to be released without the customer’s authorization.

Fields of operation

Some examples:

- Construction materials

- Hydrogen storage

- Car paints

- Lubricants

- Stem cells

- Automotive

- Conductive applications

- Strengthening of protection

- Improving propellant

- Food

- Electronics

- Aerospace

Applications & Materials

some non-restrictive examples:

- Metal and metal related powders

- Iron-oxides, superparamagnetic or not

- Encapsulation against water oxidation

- Encapsulation enhancing colour light interference

- UV protection encapsulation

- Aluminium

- Boron

- Graphene oxide

- Encapsulation with iron-oxides

- Encapsulation of edible oil

- Silicene

- Graphene

- Many others